We proudly tell anyone who will listen that we use Myonic hybrid ceramic bearings on the majority of the turbines that we build. Why is that such a big deal? Well, to answer that questions, there are about eleven other common questions that would first need to be answered and understood. Here are those questions and answers that should help you get up to speed on dental bearings. Please do not hesitate to call us if you have any other questions about dental bearings.

1. What are the design differences between radial and angular contact ball bearings?

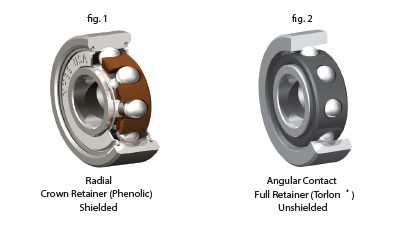

The main difference between radial ball bearings (fig. 1) and angular contact ball bearings (fig. 2) is the retainer type: radial bearings include a crown retainer (fig. 1) whereas angular contact bearings include a full retainer (fig. 2).

2. What are the benefits of radial and angular contact ball bearings? Which design offers better performance and longer life?

Radial ball bearings (fig. 1) are more convenient to use because they may be installed and axially loaded from either side. Angular contact ball bearings (fig. 2) perform better at higher speeds and operate longer, on average, than radial bearings. Angular contact bearings can only be axially loaded from one side. Keep in mind that bearing life can be significantly impacted by other factors, like whether or not you follow appropriate maintenance protocols, use a quality cleaner/lubricant, or avoid immersing their handpieces in aggressive or corrosive cleaning chemicals.

3. What is the difference between a ball bearing manufactured with a phenolic retainer and one manufactured with a Torlon® retainer?

Phenolic (fig. 1) is a porous material that may be impregnated with oil at the factory. During operation, a phenolic retainer provides continuous bearing lubrication by releasing micro-droplets of oil contained within its body.

Torlon® (fig. 2) is not porous and cannot be impregnated with oil. However, it contains solid lubricating additives, like graphite and Teflon®, which help to lubricate a dental bearing during conditions of conventional-lube starvation. Torlon® handles autoclave sterilization much better than phenolic, which has a tendency to develop micro-cracks during repeated sterilization.

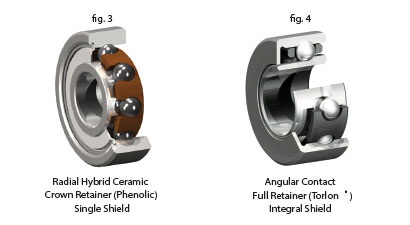

4. What is the advantage of using a hybrid ceramic ball bearing (fig. 3), which includes hardened steel rings and silicon nitride (ceramic) balls, instead of a typical bearing with steel rings and steel balls?

Ultimately, a hybrid ceramic ball bearing runs cooler and extends turbine life. A ceramic ball is approximately 60% lighter than the same size steel ball. As a result, the lighter ceramic ball-set generates less centrifugal force when operating at super-high speeds, which minimizes wear on the raceway of the outer ring. Surface wear is further reduced because ceramic and steel are such different materials. Ceramic balls are harder than heat-treated steel balls, so it’s less likely that external contaminants or bearing wear debris will damage them and cause the bearing to fail. Also, a hybrid ceramic

bearing operates better than an all-steel ball bearing in low-lubrication conditions.

5. How does sterilization affect open (unshielded) and shielded ball bearings?

In open bearings the lubricant tends to migrate out of the bearing during the autoclave cycle (sterilization process). Single-shielded, double-shielded, and integral-shielded bearings (fig. 4) are better equipped to protect against external contamination, lubricant migration, and autoclave steam.

6. What does www.Handpiece-Turbines.com suggest for maintaining a handpiece after sterilization?

We suggest following either our or the the manufacturer’s recommendations for cleaning and lubricating your dental handpieces after each patient-use and sterilization procedure (autoclaving).

7. If you buy turbines with grease-packed vs. oiled ball bearings, do I need to perform any other lube operation

before or after using the handpiece?

In terms of lubrication, there are two kinds of dental bearings: an oiled bearing, which requires intermittent oil lubrication during use, and a maintenance-free (grease-packed) bearing, which is pre-lubricated at the factory with a specified amount of special grease. Spraying a maintenance-free bearing with oil will likely flush the grease from the bearing. Therefore, if oil is used, the bearing should no longer be treated as maintenance-free; it should be treated as an oiled bearing that requires intermittent oil lubrication. Please note that steel and hybrid ceramic bearings that are lubricated with oil or a small amount of grease for run-in purposes and testing during or after the turbine installation process.

8. What is a “lube-free” bearing?

A “lube-free” bearing is a bearing that has been pre-lubricated at the factory with a specified amount of special grease; it does not require intermittent lubrication with oil. When using a turbine that has maintenance-free bearings, you should keep in mind that most grease lubricants tend to migrate out of the bearing when an external oil lubricant is used. Once oil is used to lubricate a maintenance-free bearing, that bearing must from then on be lubricated with oil.

9. What does “ABEC rating” mean?

ABEC is the acronym for “Annular Bearing Engineers’ Committee,” which works on behalf of the American Bearing Manufacturers Association (ABMA) to determine the standards for bearings. ABMA Std.12 is the ABEC standard which controls the class-level, or rating, for dental bearings. All high quality and all of Myonic’s dental bearings are manufactured to a minimum tolerance of ABEC 7.

10. How many ABEC levels are there?

The ABEC scale classifies the accuracy and tolerance ranges for bearings. The five ratings in the ABEC scale are: ABEC 1, ABEC 3, ABEC 5, ABEC 7, and ABEC 9. A larger ABEC number denotes a higher precision level.

11. What levels of accuracy and tolerance does the Myonic bearings used by www.Handpiece-Turbines.com provide?

While the dental bearings manufactured by Myonic are rated to a minimum tolerance of ABEC 7, the following characteristics meet or exceed the requirements of ABEC 7 and ABEC 9: bore, outside diameter (O.D.), width tolerances, radial and axial runout, and noise level (Myonic internal controls).